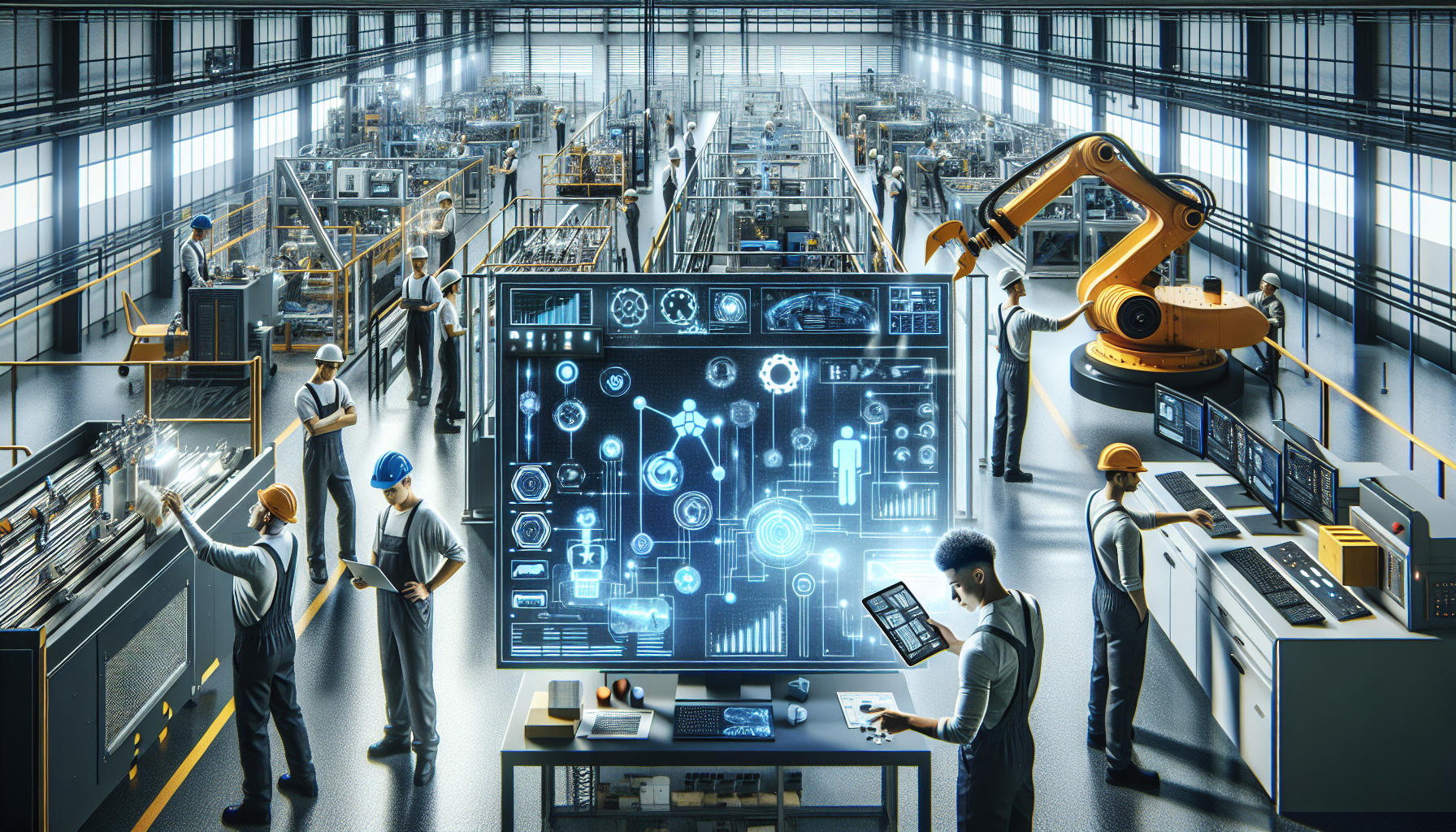

Transforming Workplace Safety through AI-Driven Material-Handling Automation

Ensuring workplace safety in industrial settings is crucial, particularly regarding manual material-handling duties. Historically, these tasks have posed risks due to the repetitive actions associated with lifting, moving, and managing heavy items. Employees frequently face injury risks from incorrect techniques or prolonged strain. Nevertheless, advancements in artificial intelligence (AI) and automation technology are enabling companies to significantly enhance safety standards.

AI-powered material handling automation not only lessens the physical burden on workers but also enables organizations to streamline their operations. This article delves into how AI is reshaping material handling, enhancing safety, and boosting operational effectiveness.

Mitigating Hazards by Undertaking Risky or Unpleasant Tasks

Manual roles in industries such as mining, manufacturing, and construction typically encompass perilous or dirty tasks, exposing workers to injury. AI-driven solutions are proving to be transformative in alleviating these dangers.

For instance, in mining, AI has been utilized for ore sorting. Advanced algorithms can identify and segregate valuable resources from waste, thereby decreasing the requirement for manual labor in hazardous conditions. This application not only augments productivity but also decreases workers’ exposure to harmful environments.

In a similar vein, conveyor systems, a mainstay in industrial material handling, are increasingly being paired with AI technology. Cameras equipped with machine learning and computer vision can assess material quality in real-time, identifying defects and guaranteeing product uniformity. This advancement minimizes the necessity for human intervention in potentially perilous areas, thus enhancing workplace safety.

Industry-Specific AI Solutions Offer Flexibility

The adaptability of AI-powered material-handling solutions is one of their most notable advantages. Vendors are developing automation tools designed to meet the distinct requirements of various industries, including manufacturing, food processing, pharmaceuticals, and logistics.

For example, companies in the food and pharmaceutical sectors are progressively switching from traditional wooden pallets to plastic ones. These plastic pallets are nonporous, making them more hygienic and suitable for sectors with strict sanitation standards. They can be effortlessly integrated with automated systems, such as collaborative robots (cobots) and AI-driven guided robots. This fusion of AI and automation aids in minimizing errors, enhancing productivity, and fostering a safer workplace by reducing human interaction with hazardous materials.

Improving Human Workflows through AI Automation

AI-driven systems for material handling are crafted to optimize workflows by taking on tasks prone to accidents or mistakes. The aim is not to displace human workers but to augment their abilities, allowing them to graduate to less hazardous and more fulfilling roles.

A prime example involves autonomous forklifts and reach trucks. These AI-enhanced machines generate over 16.5 million data points per second using cutting-edge sensors and cameras. Such systems can recognize obstacles in real-time and make instantaneous decisions to avert mishaps. While human oversight remains essential, these AI systems considerably diminish the time that workers spend on dangerous tasks, therefore lowering the risk of injury.

This movement towards automation is mutually beneficial: it safeguards employees while allowing businesses to prioritize higher productivity metrics.

AI and Responsibility: A Cooperative Framework

While AI has the potential to enhance workplace safety, it is vital to recognize that technology alone will not suffice. Workers must be trained to interact with and operate these sophisticated systems effectively. Ongoing training and updated safety policies are imperative to ensure seamless collaboration between machines and humans.

Employers should cultivate a culture of personal responsibility within their workforce. Employees need to realize that AI tools are designed to assist them, not to absolve them of their duty to maintain a secure work environment. When workers appreciate the importance of both AI systems and personal safety protocols, the outcome is a safer, more efficient, and cooperative workplace.

Conclusion

AI-driven material-handling automation is changing the landscape of workplace safety in industries. By assuming control of hazardous and monotonous tasks, AI not only safeguards workers but also streamlines procedures, reducing the likelihood of human errors. As these technologies continue to advance, their contribution to enhancing safety will become increasingly vital. However, effective implementation requires a cohesive strategy that merges state-of-the-art technology with adequate training and personal accountability.

Frequently Asked Questions (FAQs)

Q1: In what ways does AI enhance workplace safety in material handling?

AI boosts safety by assuming hazardous, repetitive, or physically demanding tasks that may result in worker injuries. These systems can independently identify dangers, maintain quality control, and drastically decrease the need for manual labor in risky settings.

Q2: Will AI in material handling substitute human workers?

No, AI is not intended to replace human workers but to support their contributions. By automating risky tasks, employees can transition into safer, higher-value positions, making workplaces more productive without displacing jobs.

Q3: How do specific industries gain from AI-driven material handling?

Industries such as food processing, pharmaceuticals, and mining are witnessing notable enhancements. AI-driven systems help ensure sanitation, improve quality management, and reduce human interaction with dangerous materials, resulting in safer and more efficient practices.

Q4: What significance does personal accountability hold when working with AI systems?

Despite the advantages AI offers, human workers must remain alert and take responsibility for their safety. Adequate training and a culture of accountability are crucial for guaranteeing effective collaboration between humans and machines.

Q5: Are there any persistent obstacles with AI in material handling?

A primary challenge is the necessity for ongoing training for workers. As AI systems develop, employees must stay informed about effectively and safely utilizing these technologies. Furthermore, ensuring that AI systems can adapt to ever-changing real-world environments continues to be an area of focus.

Q6: What does the future hold for AI in material handling?

As AI technologies become more advanced, we can anticipate even deeper integration within industries reliant on material handling. Future AI systems may become increasingly autonomous, further lessening human involvement in dangerous tasks while boosting overall efficiency.