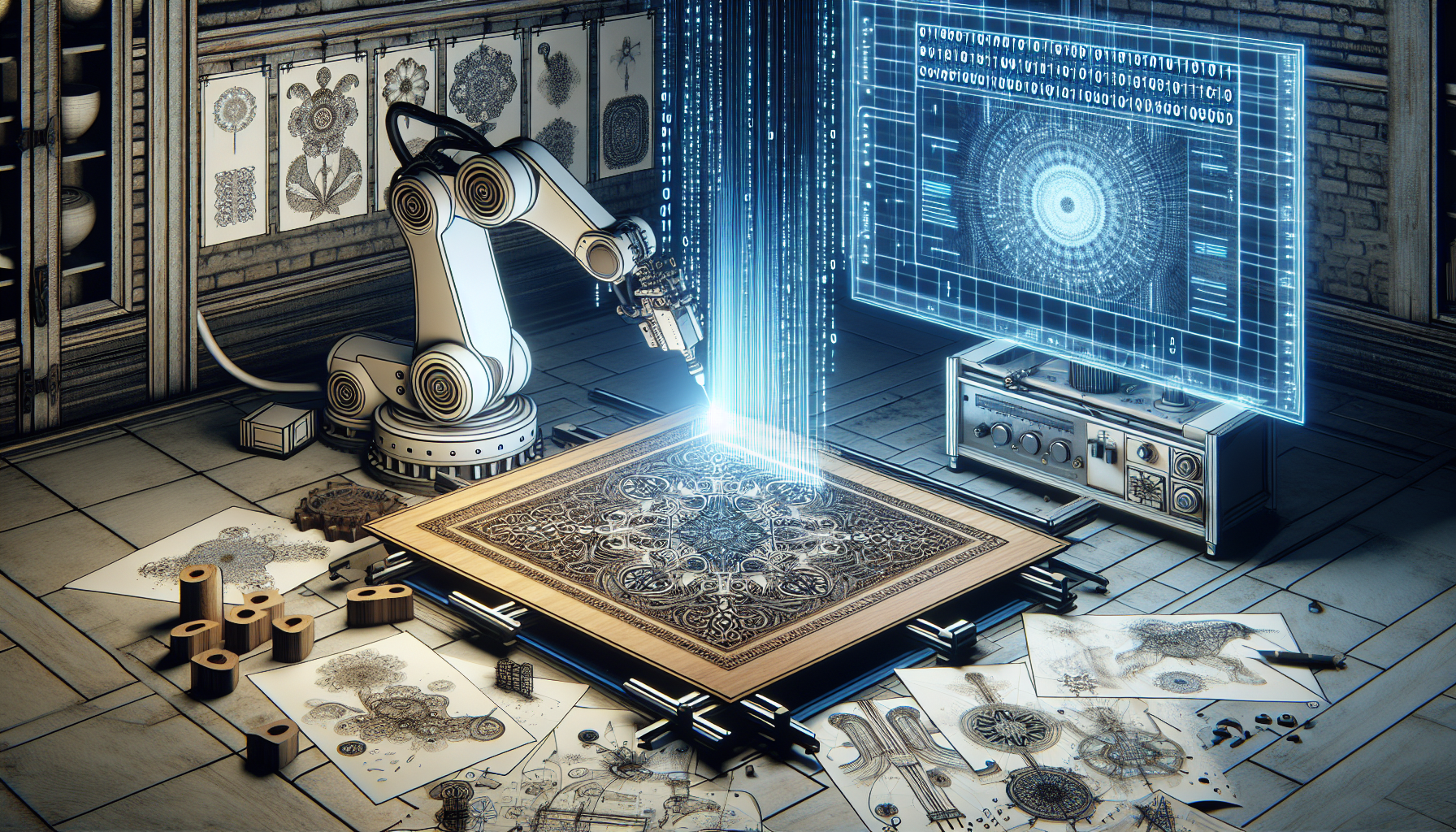

Enhancing Laser Cutting Processes with AI-Enhanced Design Developments

The progression of artificial intelligence (AI) is transforming industries on a global scale, and the laser cutting sector is no exception. By effectively incorporating automation, extensive data analysis, and machine learning into laser cutting methods, AI is tackling persistent inefficiencies and paving the way for innovative manufacturing and design solutions. This dynamic combination is fostering improvements in precision, productivity, and novel applications throughout various sectors.

Issues Encountered by Conventional Laser Cutting

For a long time, laser cutting has been a fundamental aspect of manufacturing, utilized for shaping various materials including metals and plastics. Nevertheless, conventional laser cutting systems frequently face challenges related to inefficiency and quality assurance.

Lengthy Quality Assessment Procedures

Standard procedures necessitate distinct testing and inspection stages to confirm the accuracy of each cut or weld. These extra processes not only consume time but also elevate production expenses due to high rates of rejects and material loss. Industries such as electric vehicle (EV) manufacturing, where precision is essential, experience significant impacts from these inefficiencies.

Restricted Customization and Manual Adjustments

Conventional laser systems typically depend on manual adjustments to alter settings for different materials or designs. This dependency on human operation can slow down processes, heighten the risk of mistakes, and complicate customization efforts. As the demands in manufacturing rise, these constraints underscore the urgent need for more automated and intelligent solutions.

The Role of AI in Streamlining Laser Cutting

AI is revolutionizing the field of laser cutting by introducing automation, real-time oversight, and insights driven by data. Here are three primary ways in which AI enhances the laser cutting process:

Instantaneous Quality Surveillance

A game-changing contribution of AI to laser cutting is its capacity for real-time quality surveillance. AI-driven sensors, such as those developed through partnerships between TRUMPF and SIMa.ai, can evaluate over 3,000 images every second. This capability facilitates immediate quality assessments during each cut, thereby removing the necessity for a separate inspection stage.

For sectors like EV production, this technology guarantees consistent weld quality, decreases reject rates, and minimizes production expenses. By boosting efficiency and accuracy, these sensors also play a role in making products more affordable for consumers.

Internet-Enabled, On-Demand Production

AI has ushered in the era of internet-enabled, on-demand production. Systems like the Meister Data Generator, crafted by researchers at the University of Tokyo, permit remote management of laser manufacturing. This feature enables users to design from any location, decentralizing the manufacturing framework.

Such systems lessen the need for continuous human oversight while allowing small enterprises and individuals to create customized products. On-demand production also cuts down transportation expenditures, making it an economically viable solution for numerous industries.

Integration of Big Data and Machine Learning

AI’s proficiency in processing extensive datasets is opening new avenues for laser cutting. By scrutinizing large amounts of data, AI systems gain a better understanding of laser-material interactions, enhancing precision while broadening the capabilities of laser technology.

For instance, in laser ablation—a technique that eliminates material with brief light pulses—AI can generate and assess around 1,000 high-quality data points within a single day. This degree of insight is indispensable for industries like semiconductor manufacturing, where precision is critical at the nanometer level.

Sector-Wide Applications

The convergence of AI-integrated laser cutting technologies is significantly impacting multiple sectors, presenting innovative solutions to longstanding problems.

Electric Vehicles (EVs)

In the EV sector, AI-enhanced laser cutting is essential for producing high-quality batteries. The technology guarantees precise particle detection and control, resulting in safer and more effective energy storage options.

Semiconductors

AI-driven lasers are transforming material processing in semiconductor production, where precision is of utmost importance. These innovations facilitate the creation of next-generation microchips, which are vital for contemporary electronics and technologies.

Data Centers and Telecommunications

AI-augmented lasers are revolutionizing data centers by enabling high-speed optical interconnections. These systems support the swift transmission of substantial data volumes, promoting the expansion of edge computing and telecommunications technologies like 5G and 6G. By decreasing latency and improving energy efficiency, these advancements are laying the groundwork for smarter, more interconnected urban environments.

Creative and Small-Scale Manufacturing

Internet-enabled laser systems are democratizing manufacturing, enabling small businesses and individuals to produce customized items such as bespoke jewelry and personalized medical devices. This increased accessibility is nurturing creativity and innovation on a global scale.

Scientific Research

The research community is also reaping the rewards of AI-enhanced laser systems. Swift analysis of extensive datasets is revealing new insights into laser-material interactions, accelerating discoveries in material science and precision manufacturing.

A Peek into an AI-Infused Future

As AI and laser technologies continue to advance, their integration promises even more groundbreaking innovations. Here are some anticipated developments:

- Intelligent Manufacturing Landscapes: Completely automated factories with interconnected AI systems might operate with minimal human involvement, transforming production lines.

- Sustainability Enhancements: AI-driven material optimization could greatly diminish waste and energy usage, fostering more sustainable manufacturing practices.

- Medical Progressions: Precision lasers powered by AI might elevate medical procedures such as tissue ablation, surgeries, and device manufacturing.

- Data Handling and Telecommunications: The combination of AI and laser technologies could hasten the advancement of robotics, autonomous transport, and smart urban developments.

AI is not only changing how products are manufactured but also rethinking what can be achieved. By embedding AI into laser cutting processes, industries are moving toward a future characterized by efficiency, precision, and boundless innovation.

Conclusion

The union of AI and laser cutting technologies is leading to a new wave of manufacturing and innovation. By tackling inefficiencies, boosting precision, and facilitating real-time surveillance, AI is transforming product design and production processes. From electric vehicles to semiconductors and data centers to small enterprises, the applications of AI-enhanced laser cutting are varied and transformative. As these technologies further develop, they are set to redefine industries and foster a more sustainable, connected, and innovative future.

Frequently Asked Questions (FAQs)

1. Which industries benefit most from AI-driven laser cutting?

AI-driven laser cutting has impactful applications in various sectors, including electric vehicle (EV) manufacturing, semiconductor production, telecommunications, and small-scale creative manufacturing. It improves precision, decreases waste, and enables customization, rendering it invaluable across many fields.

2. In what ways does AI enhance the quality of laser cutting?

AI-powered sensors allow for real-time quality assessment by analyzing thousands of images each second. This ensures consistent outcomes, lowers reject rates, and negates the requirement for separate testing stages, ultimately boosting efficiency and reducing costs.

3. What does internet-based, on-demand manufacturing entail?

This concept refers to AI systems that enable the remote control of laser cutting processes via the internet. Users can create designs from any location, facilitating decentralized production and reducing logistical costs.

4. How does AI influence sustainability in laser cutting?

AI promotes sustainability by optimizing material use, cutting down waste, and decreasing energy consumption. These efficiencies support more environmentally friendly manufacturing approaches.

5. Can small businesses gain from AI-driven laser cutting?

Absolutely! Internet-based laser systems empower small enterprises and individuals to produce custom products without the necessity for large factories, enhancing accessibility and encouraging innovation.

6. What role does big data play in laser cutting?

Big data analytics enables AI systems to comprehend laser-material interactions more accurately. This enhances cutting precision and broadens the capabilities of laser technology, particularly in precision-critical industries like semiconductor manufacturing.

7. What future possibilities can we expect from AI-powered lasers?

Upcoming advancements could encompass fully automated manufacturing environments, enhanced sustainable production techniques, improved medical applications, and advanced data processing solutions for technologies like robotics, self-driving cars, and smart cities.