## Artificial Intelligence Bolstering Quality Control in Medical Manufacturing

## Artificial Intelligence Bolstering Quality Control in Medical Manufacturing

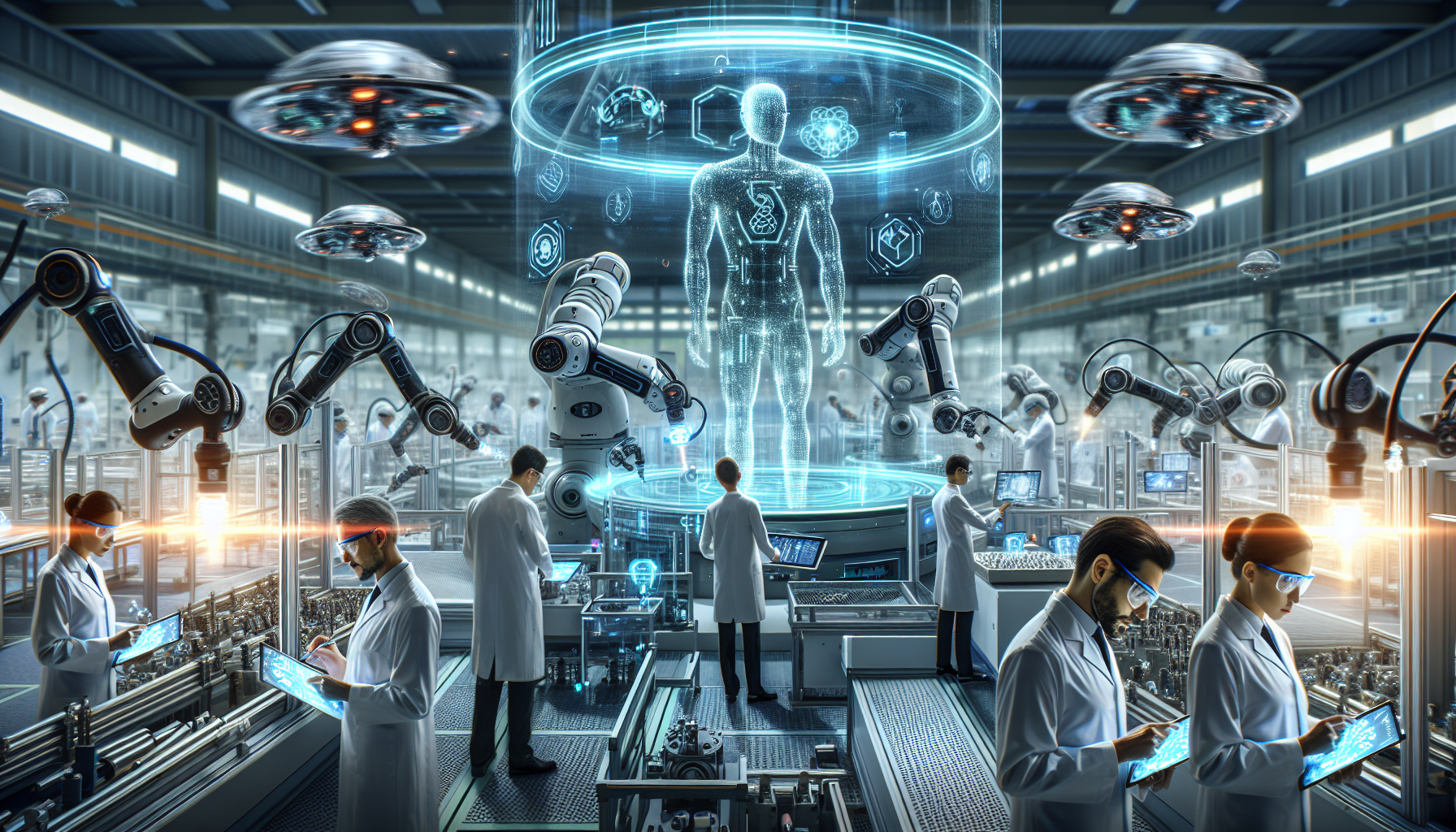

Artificial Intelligence (AI) is rapidly revolutionizing the medical manufacturing industry. By streamlining and refining the quality assurance (QA) process, AI enables faster research & development (R&D) and more accurate error detection.

Speeding Up R&D with AI

AI plays a pivotal role in pharmaceutical quality control, beginning with the research and development phase. Machine learning models can simulate drug interactions, revealing the most promising candidates for new medicine development without the need for time-consuming real-world tests.

Moderna’s use of AI in synthesizing and testing over 1,000 mRNA strands a month for COVID-19 vaccine research is a prime example of this. Traditional manual methods could only yield 30 strands within the same timeframe.

AI also streamlines the clinical trial process following the selection of an ideal drug candidate. Machine learning predicts real-world outcomes at-scale based on lab tests and analyzes demographic data to identify ideal testing areas and populations. This results in less time spent in the planning phase and improved R&D accuracy, ensuring high-quality pharmaceutical products from the start.

Fast and Precise Error Detection with AI

AI provides a more efficient alternative to manual quality inspections in the production process. Traditional end-of-line QA checks often create bottlenecks, as thorough product inspection is slower than the speed of manufacturing. This is true particularly for pharmaceuticals, where processes like cryo grinding produce particles as small as 10 micrometers, necessitating highly precise inspections.

Machine vision, an AI application, can perform these inspections significantly faster than humans. AI quality inspection systems can analyze pharmaceuticals as quickly as production lines produce them. Additionally, AI outperforms humans in accuracy, delivering consistent standards every time.

Minimizing Human Error in Production

AI applications minimize human error in pharmaceutical manufacturing by making production less prone to mistakes. Collaborative robots enhance assembly precision, while AI features like machine vision make them more adaptable, reducing both human and machine-related errors.

AI can also analyze digital twins of production lines to identify where errors occur. Some models can even suggest potential changes, enabling pharma companies to refine their workflows and make quality mistakes less likely. This leads to fewer flawed medicines reaching the final QA inspection and less time spent on correcting errors or removing defective medicines, increasing both product quality and production efficiency.

Conclusion

With growing public health concerns, pharmaceutical manufacturers are increasingly pressured to boost their throughput and QA. Achieving this with entirely manual workflows is challenging. AI provides the necessary speed and accuracy to meet these demands.

AI is already making a significant impact, especially in the R&D phases of pharmaceutical manufacturing. As this trend continues, more pharma companies will likely adopt this technology in their processes, leading to higher efficiency and quality standards across the industry, thanks to AI.

Questions and Answers

Q1: How does AI aid in the research and development phase of pharmaceutical manufacturing?

A1: AI uses machine learning models to simulate drug interactions, identifying the most promising compounds for new medicines without time-consuming real-world tests. It also streamlines the clinical trial process by predicting real-world outcomes based on lab tests and analyzing demographic data.

Q2: How does AI improve quality inspections in the production process?

A2: AI uses machine vision to perform inspections much faster and more accurately than humans. It can analyze pharmaceuticals as quickly as they are produced and consistently deliver high standards of inspection.

Q3: How does AI help minimize human error in production?

A3: AI applications, such as collaborative robots and machine vision, make production less prone to mistakes. AI can also analyze digital twins of production lines to identify and suggest changes to reduce errors in workflows.

Q4: What is the overall impact of AI on pharmaceutical manufacturing?

A4: AI is revolutionizing the pharmaceutical manufacturing industry by speeding up research and development, improving error detection, and minimizing human error in production. This leads to increased product quality, production efficiency, and industry-wide improvements in efficiency and quality standards.