Apple Relocates iPhone Production to India: Implications for the Future of Tech Manufacturing

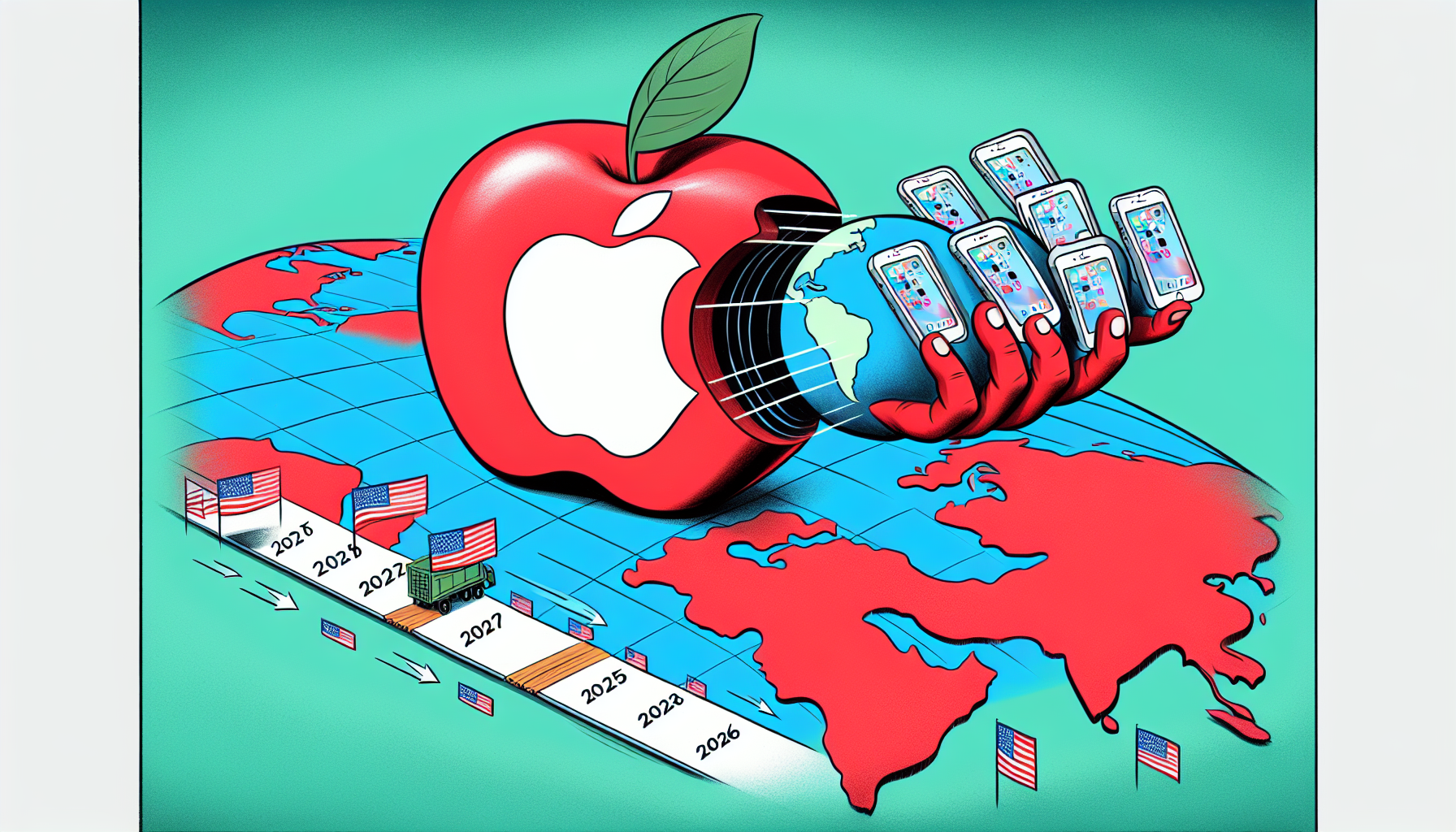

In a pivotal decision that may transform global supply chains and alter the landscape of tech manufacturing, Apple has revealed its intention to shift its entire iPhone production aimed for the U.S. to India by 2026. This transition comes in response to rising trade tensions between the United States and China, marking a significant change in Apple’s global production strategy.

Reasons Behind Apple’s Move to India for iPhone Production

Increasing Tariffs from the U.S. and China

A key factor driving Apple’s shift is the mounting tariff pressure from Washington upon Beijing. In recent years, the U.S. government has enacted several rounds of tariffs on goods produced in China, impacting tech companies like Apple. By moving iPhone assembly operations to India, Apple can avoid these tariffs and prevent increased costs from being passed on to consumers.

Diversification of Supply Chain

Apple’s reliance on China for manufacturing has long raised concerns among investors and analysts. The COVID-19 pandemic highlighted the risks associated with depending on a single nation for production. By relocating iPhone assembly to India, Apple seeks to establish a more robust and diverse supply chain capable of handling geopolitical and health-related challenges.

Rising Manufacturing Potential in India

India is becoming a more appealing location for electronics manufacturing. Government programs such as “Make in India” coupled with incentives for foreign direct investment have facilitated the establishment of production facilities. Furthermore, India’s abundant skilled workforce and rapidly improving infrastructure make it a suitable alternative to China for high-tech production.

Apple’s Expansion of Manufacturing in India

Doubling iPhone Production

Apple aims to increase its iPhone production in India to over 60 million units per year by the end of 2026. Achieving this target will require substantial investments in local manufacturing infrastructure and workforce development. Apple is already collaborating with Indian manufacturers such as Foxconn, Wistron, and Pegatron to set the foundation for this growth.

Initial Development of the iPhone 17

In a groundbreaking move, an Indian facility has engaged in the preliminary development of the iPhone 17. Historically, this initial phase—where prototypes are developed into designs ready for mass production—has been executed in China. The participation of Indian engineers in this process is a landmark sign of Apple’s growing confidence in India’s technical expertise.

During this critical phase, the team in India focused on refining the iPhone’s design, experimenting with new materials, and testing cutting-edge production technologies to ensure that mass production can proceed with minimal defects across various locations.

Challenges That Lie Ahead

Scaling Manufacturing to Fulfill U.S. Demand

Even with progress, the scale of the tasks ahead is substantial. The U.S. market requires millions of units annually, and Indian factories must quickly enhance their production capacities. This entails not just physical infrastructure but also efficient supply chain management, quality assurance, and workforce preparedness.

Ensuring Quality Standards

Apple is renowned for its strict quality control, and matching the consistency of Chinese manufacturing in India will require considerable time and effort. The company will need to heavily invest in staff training and quality assessment processes to ensure that the devices produced meet the high standards customers expect.

Implications for Consumers

Possible Price Stability

By steering clear of Chinese tariffs, Apple might be able to keep current pricing for its iPhones steady despite rising global inflation and supply chain expenses. This is especially crucial at a time when consumers are increasingly cautious about pricing.

Upcoming “Made in India” Labels

U.S. consumers may start seeing “Made in India” labels on their iPhones as soon as 2026. This shift could also affect public perception as consumers grow more aware of the origins of their devices and the complexities of global tech manufacturing.

Broader Effects on the Tech Industry

Creating a Model for Other Tech Firms

Apple’s decision could set a precedent for other tech companies aiming to diversify their supply chains. As India enhances its manufacturing framework, additional brands may follow suit, fostering a greater decentralization of tech production.

Boosting Investment in Indian Infrastructure

With Apple spearheading this initiative, India is likely to witness an escalation in investments towards infrastructure, logistics, and training programs. This development could further solidify the nation’s status as a global manufacturing leader.

Final Thoughts

Apple’s plan to transfer its U.S. iPhone production to India by 2026 signifies a landmark transition in global tech manufacturing. Prompted by tariff challenges, supply chain vulnerabilities, and India’s expanding capabilities, this move is set to transform the electronics production landscape. Although obstacles in scaling and maintaining quality persist, the potential advantages for both Apple and its consumers are considerable. As “Made in India” becomes a common label on iPhone packaging, this transition could herald a new era in global manufacturing.

Frequently Asked Questions (FAQs)

1. Why is Apple shifting iPhone production to India?

Apple is moving its iPhone production to India mainly to navigate U.S.-China tariff issues, diversify its supply chain, and leverage India’s expanding manufacturing strengths.

2. When will the transition be finalized?

Apple intends to have the entire U.S.-bound iPhone production operate from India by the conclusion of 2026.

3. Will the quality of iPhones produced in India be consistent?

Yes. Apple is known for adhering to strict quality benchmarks, and the company is making significant investments in training and infrastructure to ensure that iPhones made in India uphold the same quality as those from China.

4. How might this transition impact iPhone pricing in the U.S.?

By relocating production, Apple aims to circumvent additional tariffs, which may help keep or even lower future iPhone pricing for American consumers.

5. Is this the first instance of India participating in iPhone development?

Yes, for the first time, an Indian factory has been engaged in the early development process of the iPhone 17, indicating a significant advancement in Apple’s trust in Indian manufacturing skills.

6. Will Apple produce other items in India as well?

While the immediate focus lies on iPhones, it is possible that Apple may eventually broaden its Indian manufacturing to include other devices such as iPads, Macs, or Apple AirPods.

7. Could this decision influence other tech firms?

Certainly. Apple’s strategy may motivate other tech giants to view India as a viable manufacturing alternative to China, potentially leading to a shift in the global tech production environment.